Four years ago I made a huge leap and became an airplane owner. Owning my own plane has opened up a whole world of new opportunities. I have made many cross country trips from my home base of Minnesota to AirVenture, Sun-N-Fun, the Bahamas, Mount Rushmore, and the list goes on. In addition I used the Mooney for training by adding Commercial Pilot and Flight Instructor ratings. In total between my son and I, we have put over 400 hours on the plane. In that time we have experienced very few maintenance issues, nothing I would consider more than routine maintenance.

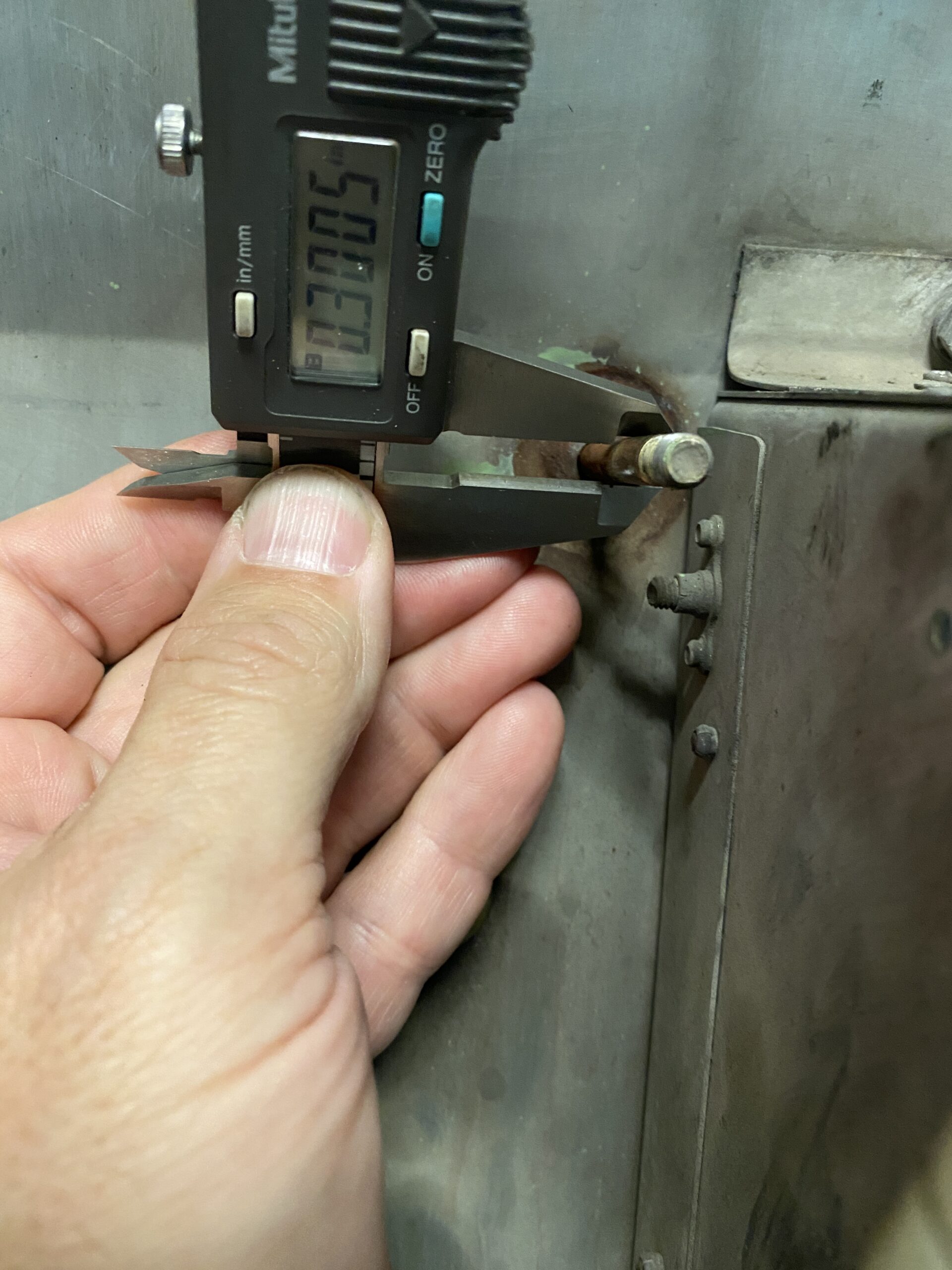

My luck has run out. On my last flight I had another incident of engine vibration and a drop in EGT on one cylinder. Rather than following previous mechanics advise that this was just fouled spark plugs I brought in a mechanic to take a closer look at the engine. After looking at the condition of the exhaust valve on the #4 cylinder it was decided that the cylinder would need to be replaced. Removing the cylinder allowed us to finally examine the condition of the engine internals and we discovered that the camshaft lobe and valve lifters were failing due to corrosion and spalling. Unfortunately this is a fairly common problem.

At this point there I have no option other than to remove the engine since the lifters cannot be replaced without splitting the engine case. With this engine being so close to the recommended 2000hr TBO it would be foolish to not do a complete overhaul. So I have begun a new chapter in the airplane ownership experience.

The Teardown Begins

With the help of my family and neighbors I have begun the process of removing the engine from the airframe. Unfortunately, this is the easiest part of the process. Carefully removing the propeller, exhaust, and disconnecting hoses and wiring to get access to the mounting bolts was not terribly difficult. Next, I borrowed an engine hoist from a neighbor and within a couple hours the engine was off the plane. It is eye opening when you see how small the bolts are that anchor the motor mount to the aircraft.

As I said, that was the easy part. For the past several weeks I have been on the phone and internet contacting countless vendors to get estimates and research my options on inspecting, repairing, or outright overhauling the various components. The costs can vary wildly and so does the scope of work. When talking to engine overhaul shops you are presented with a mind boggling array of options. Do you want new, overhauled, or PMA cylinders? Do you want to reuse your cam or buy a new cam? Do you want a Lycoming or Superior cam? Then there is the list of accessories to be overhauled; Starter, fuel pump, fuel servo, propeller governor, oil cooler, the list goes on. Some shops include some accessories, others include none. You have to do your homework to compare one proposal from the next. And just when you think you have it figured out, you get an email from AOPA. The staff at Pinnacle Aircraft Engines are Just Plane Radio Listeners. In spite of that, they contacted Tom Haines at AOPA knowing that he could get in contact with me. After talking to Aron and J.D. at Pinnacle , it was an easy decision to use Pinnacle Aircraft Engines to do the overhaul. Their pricing, scope of work, and reputation for quality exceeded every other vendor I had been considering.

Grounded

You are probably wondering how long will this take? If everything goes according to plan it should take six to eight weeks for the engine to be rebuilt. Unfortunately there are some significant headwinds to this timeline. The most critical is a lack of new cylinders. So we are pressing ahead and keeping our fingers crossed that inventory will arrive in time.

With the engine off the plane, now is the time to go through everything else from the firewall forward. It really makes zero sense to reuse fuel and oil lines from 1997 so I am having new hoses assembled. The last thing I would want to do is have a hose fail due to age or wear and potentially damage the new engine.

The oil cooler is being overhauled by Pacific Oil Cooler Service where they will ultrasonically clean the cooler inside and out, remove any old bugs or debris from the cooling fins and return it in like new condition. This will ensure that the oil is able to shed excess heat and keep the engine at a safe operating temperature.

The same logic applies to the engine mount. The mount is being sent Aerospace Welding in Minneapolis to be cleaned, sand blasted, inspected, and to repair any cracks, abrasion, or other damage prior being repainted. Again this is a case of not wanting to remove the engine again later because of something we can fix now.

The Propeller is also boxed up and being shipped out to Stallings Aircraft Propeller for a full tear down and inspection. The propeller blades will be stripped of their old paint. Bearings will be inspected or replaced. New seals and grease installed in the hub. Protective coatings and fresh paint will be applied to the blades. Once that is done, the propeller will be balanced to ensure smooth, vibration free operation.

For more information on overhauling your engine or accessories, contact the companies I trusted with my engine overhaul.