JD and the team at Pinnacle Aircraft Engines had the Mooney's engine assembled and ready run. They offered to wait on the first startup to give me an opportunity to travel to their facility and witness the engine run first hand. I couldn't pass this opportunity up. I quickly booked tickets on Delta and RSVP'd to JD that I would be there on Monday.

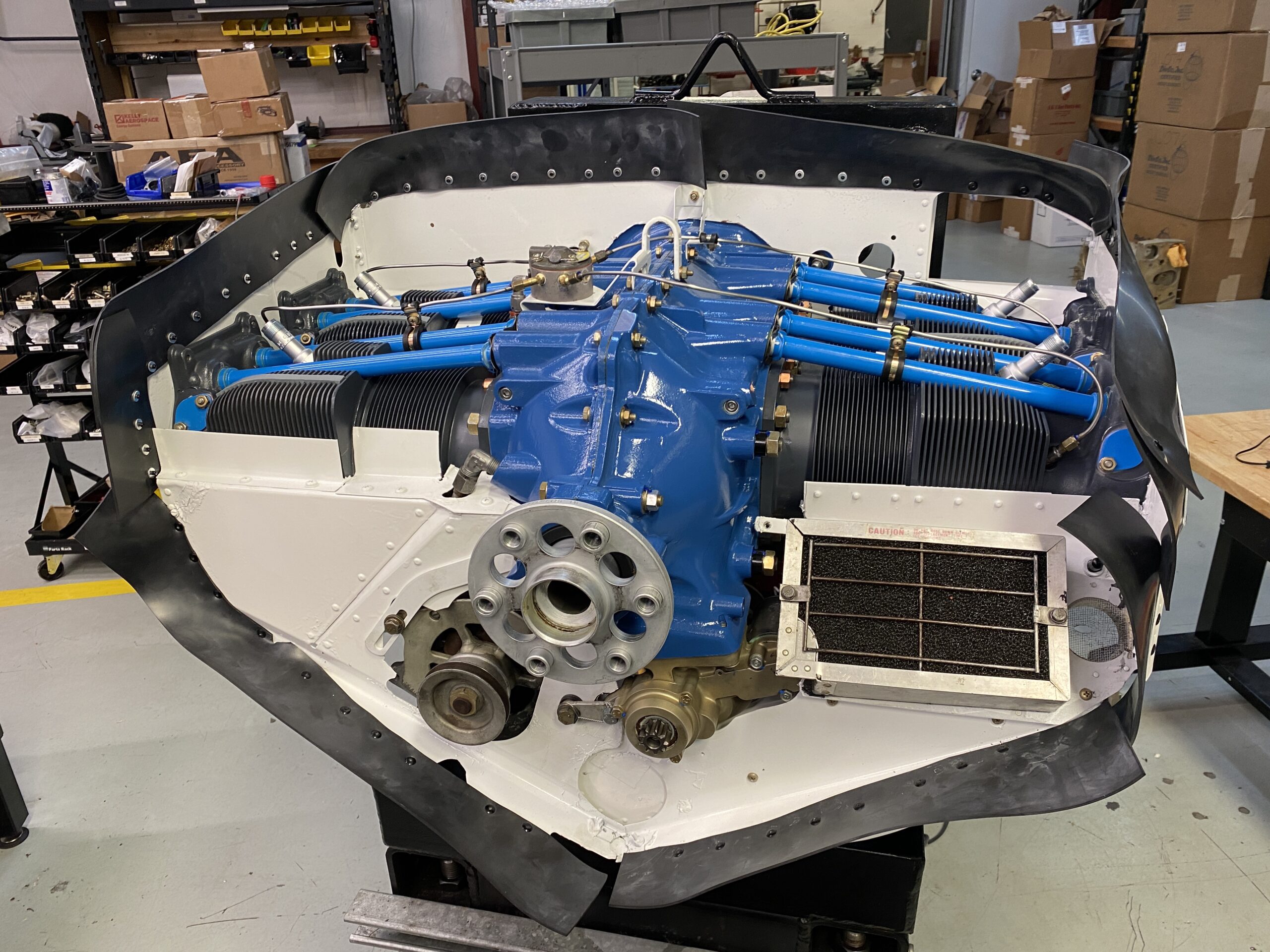

Despite having to wake up at 4am for my flight and a 45 minute drive from Pensacola to Silverhill, AL I arrived at Pinnacle's facility excited to finally see my engine. JD didn't waste a second and escorted me straight to their engine test cell. There was the Mooney's IO-360. It looked amazing with the new cylinders, paint, and overhauled accessories. Even shrouded by the test cell's instrumentation and venting it was striking

I was then taken on a tour of the facility where I was able to see how his team starts with customers worn and tired engines, transforming them into better than new condition. There is a surprising amount of work involved in overhauling aircraft engines. From disassembly they carefully inspect and measure all the components. Parts that do not meet tolerances or are damaged get replaced. Components that pass inspection are then put through further processing to perform like new. Much of the rework is done in house, however, they use a number of well known vendors for specialized work such as case refurbishment or crankshaft grinding.

For my engine, JD took on the challenge personally. Being the “Big Kahuna/Big Cheese, etc” means he doesn't get to spend as much time actually building engines so he took over a back room, locked the door and rekindled his passion with wrenching. As you can see by the pictures, he is an artist. The attention to detail really shows. Even the engine baffles were repainted and the silicone gaskets replaced. He went so far as to use black rivets to contrast with the white baffles.

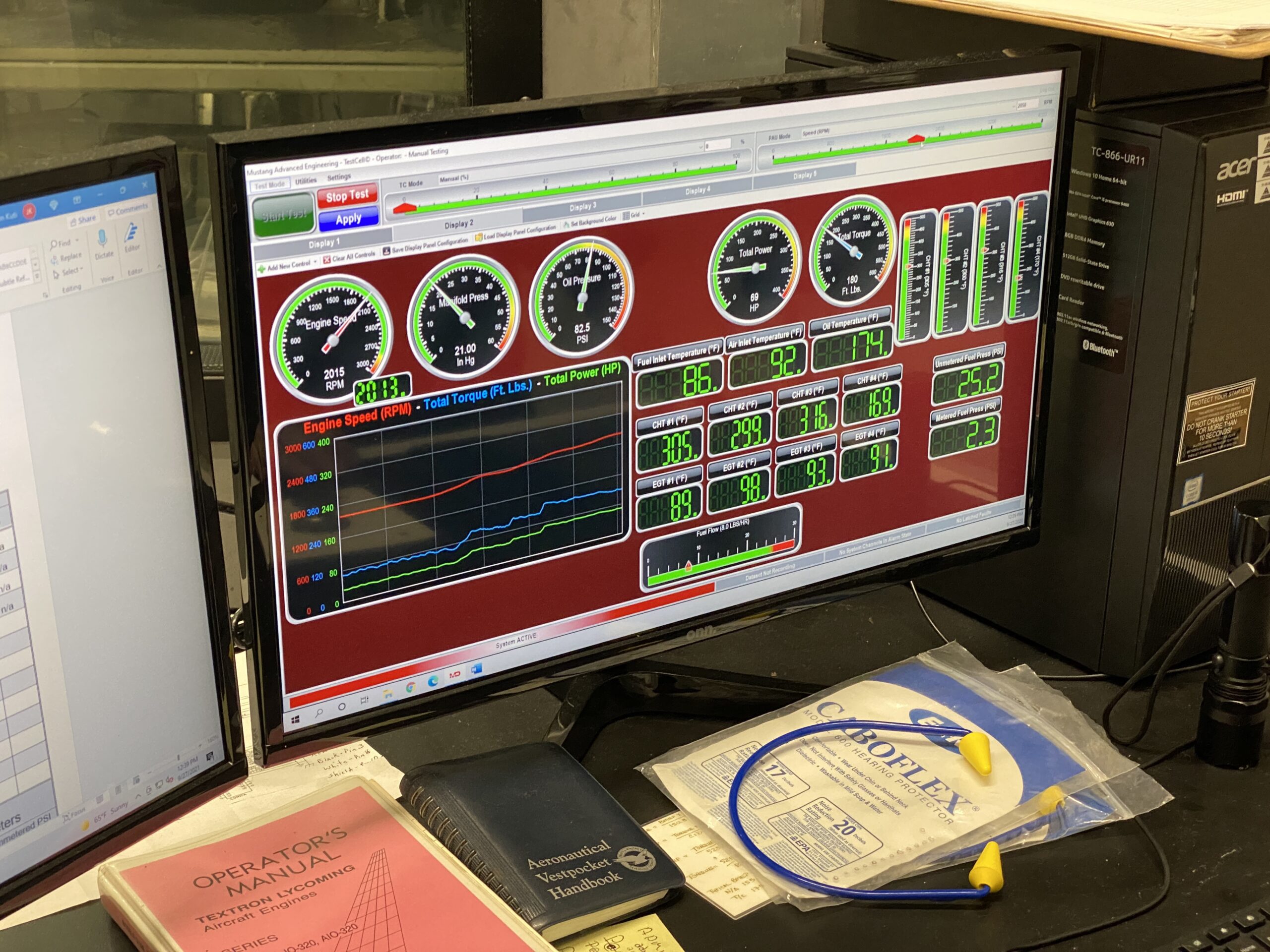

Soon it was time for the moment we have all been waiting for. The doors to the test cell were closed, fans turned on and with much anticipation I was standing at the Dyno control panel while they turned the key and started the engine. After several seconds of cranking, the engine started to huff and puff as it burned off the excess oil from the assembly process. In short order it settled into satisfying rhythm. The engine was allowed to idle leisurely at 1600 RPM while we waited for the temperatures of oil and cylinders to stabilize. From there the test plan was to slowly increase the engine power over the next 30 minutes until we are running at the redline of 2700 RPM. The engine was then slowly backed down to a low idle to cool down. After shutdown some final adjustments were made to the fuel injection to adjust the mixture and we took a break ourselves.

After lunch a second test run was made following the same protocol as the first run. When we got back up to redline RPM calculations were performed to determine the actual HP output. This engine is rated by Lycoming at 200HP. After the rebuild, it is actually making 201.5HP!

Once the test run was completed the engine was moved back out to the build area where the Pinnacle team proceeded to put all the accessories and baffling back on the engine and to prepare it for shipping. Al that was left was for me to pay the bill. My wallet may be lighter now, but I look forward to many years of safe dependable service from my Pinnacle overhaul.